Infinite options.

Infinite possibilities.

A high performing prefabricated building envelope with design flexibility.

Infinite benefits.

Sustainable

High performance

Manufactured offsite

Integrated scope

Design flexibility

Reduced risk

Infinite expertise.

Clark Pacific and Wells are both licensed manufacturers of Infinite Facade. You can expect the same great quality product wherever your project may be located. Through our partnership, we accelerate the research, development and evolution of lightweight prefabricated building envelope systems.

Infinite options.

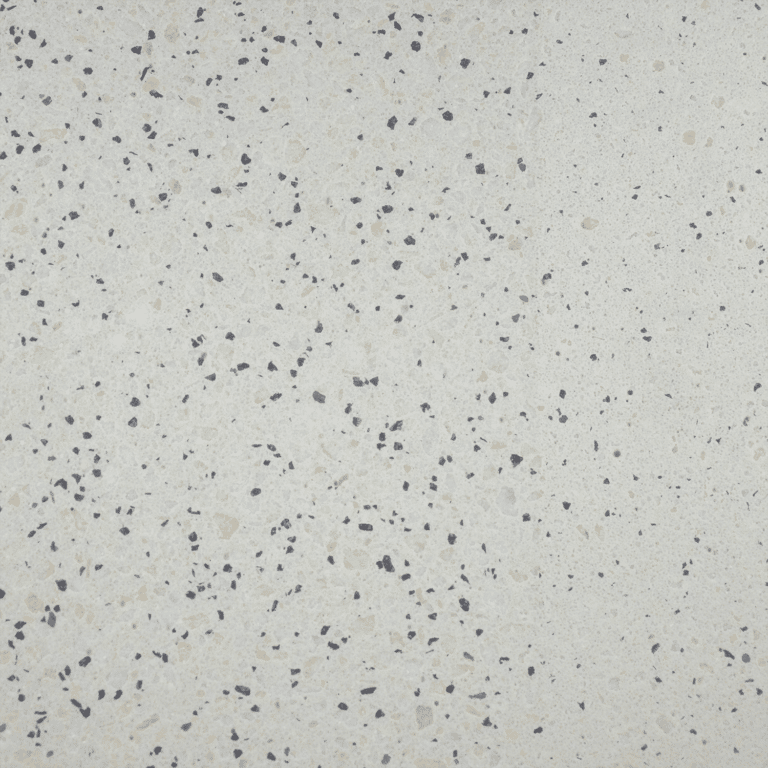

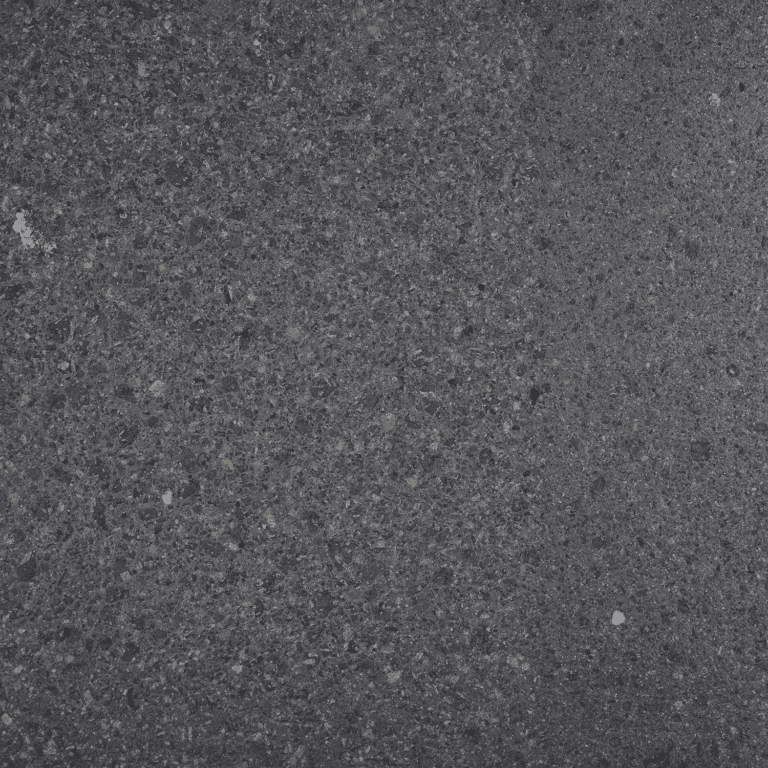

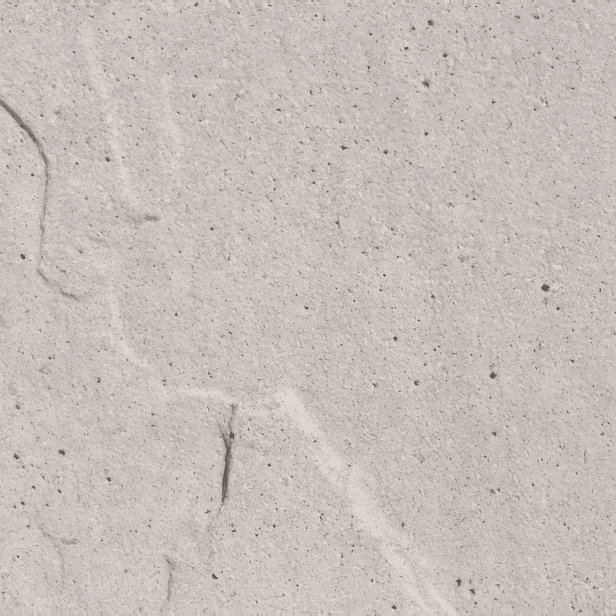

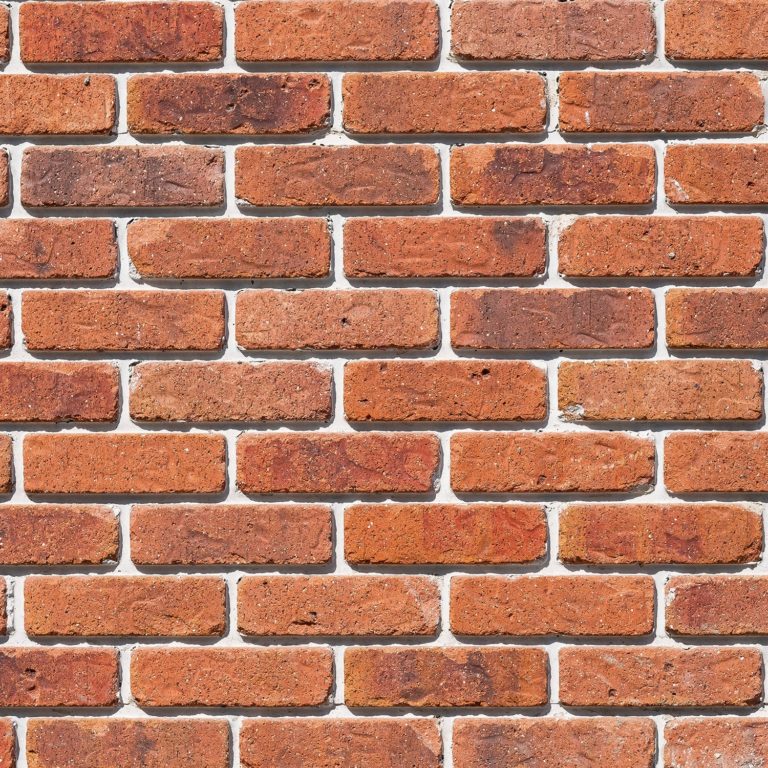

In addition to the wide variety of colors and textures available, other material can be cast into the exterior veneer- such as brick, terracotta and stone. The use of form liners also allows for an endless number of geometric pattern and reveals to be incorporated into the design.

Heavy Sandblast & Polished

Infinite efficiency.

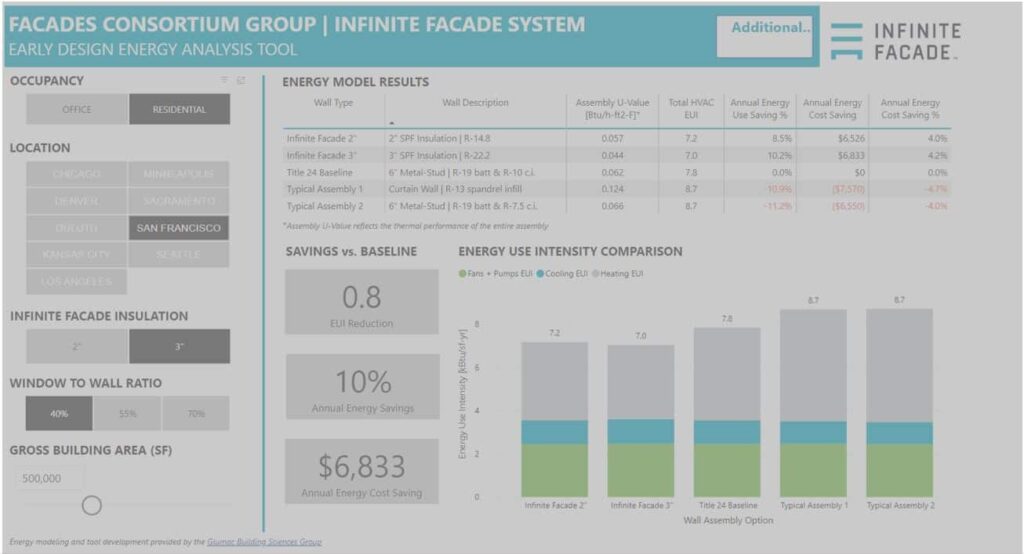

Explore the power of our advanced energy analysis tool to discover the potential energy savings. With our user-friendly interface, determine the reduction in Energy Use Intensity (EUI), percentage of annual energy savings, and associated costs specific to your project’s geographical location. Effortlessly compare Infinite Facade window-to-wall options to identify the most efficient solution for your needs. Start your exploration today and harness the energy-saving benefits of Infinite Facade.

Infinite solutions.

To best meet window and daylighting needs use one or all three configurations on the project to achieve the design intent.

Infinite Facade 75

Infinite Facade 85

Infinite Facade 100

Infinitely responsible.

- Reduces heating energy by ~30%, compared to typical construction assemblies

- Global warming potential (GWP) reduced by over 60%, compared to traditional curtain wall systems.

- Reduced cement mix by 35% and supplemented with cementous materials – reducing GWP overall by 20%

Blog Posts